Top Stories from Sky News

-

Sunak pledges to remove benefits for people not taking jobs after 12 months

Sunak pledges to remove benefits for people not taking jobs after 12 monthsPeople who are fit to work but do not accept job offers will have their benefits taken away after 12 months, the prime minister has pledged.

-

Met Police apologises for using phrase 'openly Jewish' as campaigner accuses force of 'victim-blaming'

Met Police apologises for using phrase 'openly Jewish' as campaigner accuses force of 'victim-blaming'The Metropolitan Police has apologised after an officer prevented an antisemitism campaigner from crossing a road near a pro-Palestinian march because they were "openly Jewish".

-

Police 'reviewing information' about ex-Tory MP Mark Menzies after alleged misuse of funds

Police 'reviewing information' about ex-Tory MP Mark Menzies after alleged misuse of fundsPolice say they are reviewing "information" about former Conservative MP Mark Menzies after Labour asked for an investigation into claims he misused party funds.

-

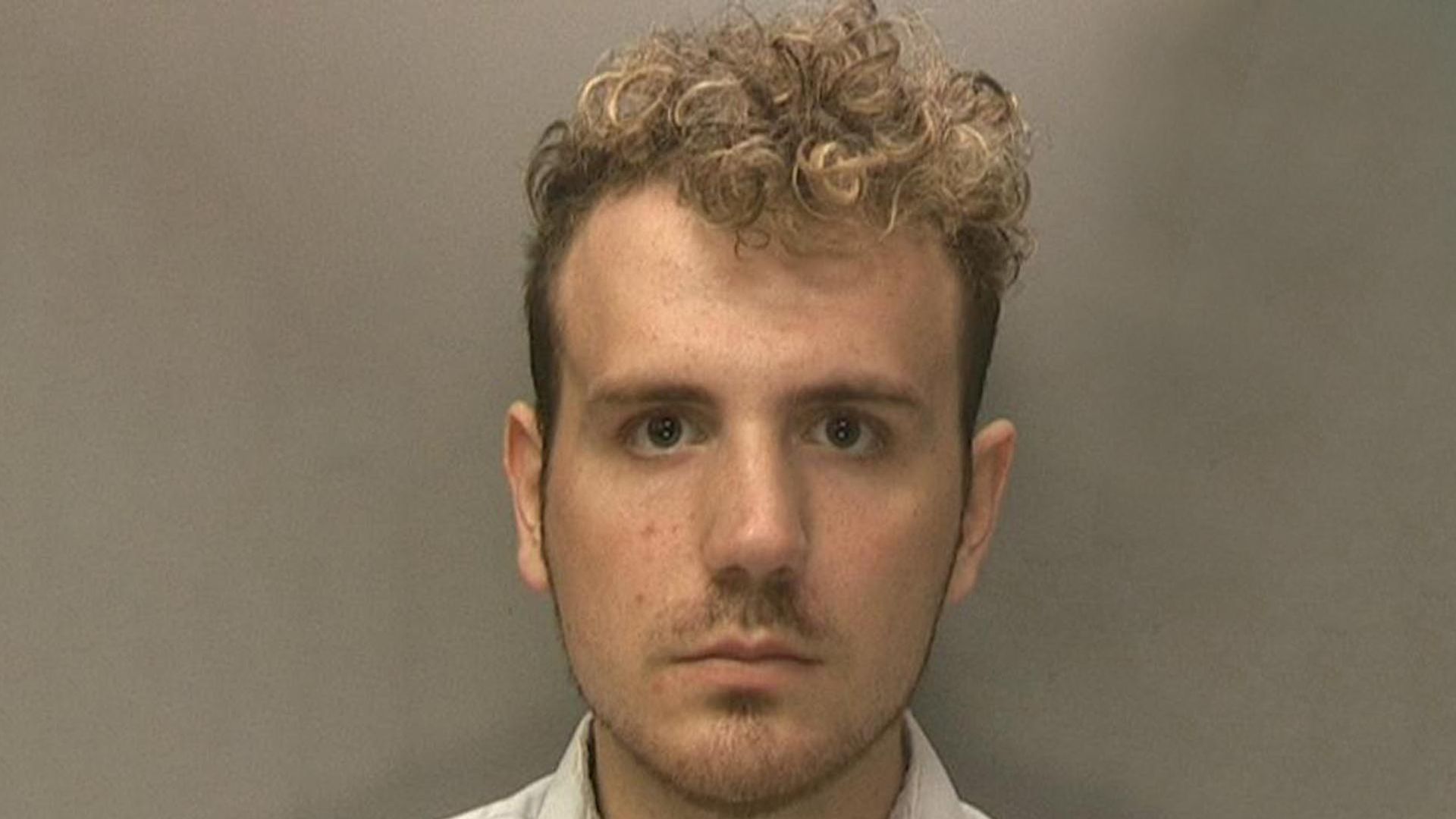

SWAT team shot man in face after UK gamer faked hostage situation

SWAT team shot man in face after UK gamer faked hostage situationA British video gamer who faked a hostage situation leading to another man suffering life-changing injuries after armed units were tricked into shooting him has been sentenced in the first case of its kind in the UK.

-

Bloody Sunday: No perjury charges for former soldiers or alleged IRA member

Bloody Sunday: No perjury charges for former soldiers or alleged IRA memberFifteen former soldiers and an alleged IRA member investigated for perjury during the Bloody Sunday Inquiry will not face charges.

-

Sturgeon admits to 'incredibly difficult time' after husband charged over embezzlement probe

Sturgeon admits to 'incredibly difficult time' after husband charged over embezzlement probeNicola Sturgeon has described her personal situation as "incredibly difficult" after her husband was charged in connection with the embezzlement of SNP funds.

-

Boris Johnson breached rules by being 'evasive' over links to hedge fund

Boris Johnson breached rules by being 'evasive' over links to hedge fundFormer prime minister Boris Johnson has breached government rules by being "evasive" about his links to a hedge fund that set up a meeting between him and the president of Venezuela, a watchdog has said.

-

Painting stolen in Oxford raid found in Romania but other works still missing

Painting stolen in Oxford raid found in Romania but other works still missingAn "'irreplaceable" 17th Century artwork stolen from an Oxford University Gallery has been found in Romania - but police say they're still hunting for two more paintings taken in the heist.

Top Entertainment Stories from Sky

-

Marriage, babies and bad boyfriends: Breaking down Swift's new album

Marriage, babies and bad boyfriends: Breaking down Swift's new albumAs the title suggests, The Tortured Poets Department is a break-up album, and one that doesn't disappoint in deconstructing Taylor Swift's failed relationships and old boyfriends gone bad.

-

Taylor Swift reveals 'secret' double album in '2am surprise'

Taylor Swift reveals 'secret' double album in '2am surprise'Taylor Swift has revealed her latest release is a "secret double album" - with 15 more tracks than fans were expecting.

-

Taylor Swift's boyfriend hails latest album as 'unbelievable' - as new track appears to say farewell to British ex

Taylor Swift's boyfriend hails latest album as 'unbelievable' - as new track appears to say farewell to British exTaylor Swift is one of the world's best-selling artists, a billionaire, and a record breaker. And she's just 34.

-

The hidden meanings in the lyrics of Taylor Swift's new album - and who she appears to reference

The hidden meanings in the lyrics of Taylor Swift's new album - and who she appears to reference"An anthology of new works that reflect events, opinions and sentiments from a fleeting and fatalistic moment in time."

Business News

-

Grocery delivery app Getir prepares to exit UK market

Grocery delivery app Getir prepares to exit UK marketGetir, the grocery delivery app once valued at nearly $12bn (£9.7bn), is close to pulling the plug on its operations in Britain in a move that would spark concerns for well over 1,000 jobs.

-

Pension funds brace for £30bn hit from Gove leasehold reforms

Pension funds brace for £30bn hit from Gove leasehold reformsPension funds are braced for a hit worth tens of billions of pounds as Michael Gove, the levelling up secretary, tries to salvage his ambition of overhauling Britain’s centuries-old property leasehold system.

-

Post Office lawyer 'takes no pride' working for the company

Post Office lawyer 'takes no pride' working for the companyA lawyer for the Post Office at the height of the Horizon IT scandal has told the public inquiry he feels "no pride" to be employed by the company.

-

Sunak pledges to remove benefits for people not taking jobs after 12 months

Sunak pledges to remove benefits for people not taking jobs after 12 monthsPeople who are fit to work but do not accept job offers will have their benefits taken away after 12 months, the prime minister has pledged.